R&D and Innovation in Pimas SRL

Hardware Development

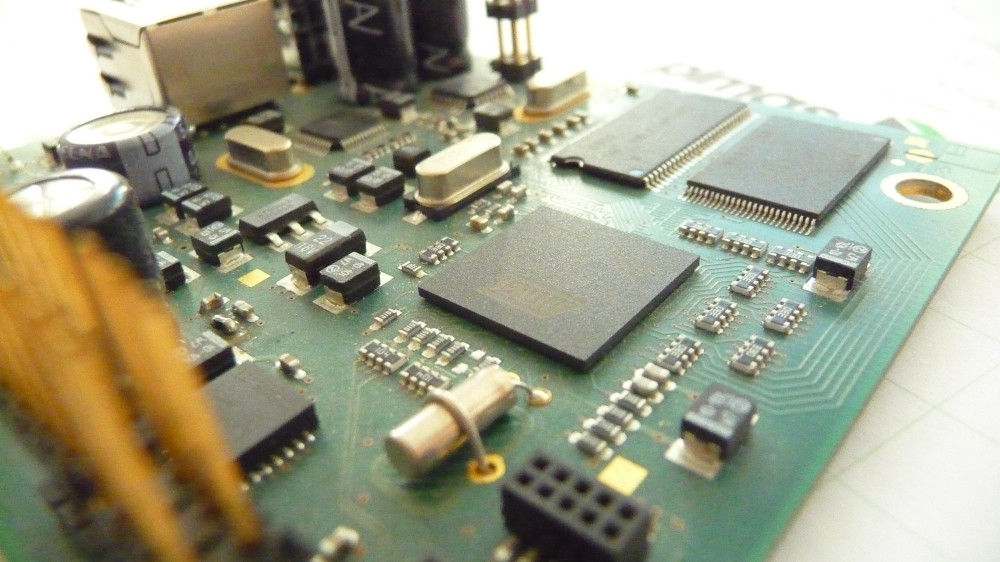

It is important to underline that usually projects start from hardware development.

Thanks to its technical know-how and the collaboration with the University of Padua, Pimas studies every application before starting with solutions in terms of:

-

master and PCB

-

electronic components (signal and power electronic)

-

control strategy

-

human-machine interface (HMI)

After the PCB realization, Pimas is able to follow all the development phases of a complete machine, like for example an electrode welding machine, an induction heating systems, a motor control equipment...

Software and firmware Development

Pimas is known as a company wiht a strong experience in the world of modern algorithm software for many kinds of processors.

In details, Pimas mainly uses :

-

microprocessors based on Arm-Cortex for the process management and the HMI interface;

-

low consume processors (for example MSP430) for the application with batteries.

Moreover through the DSP firmware, PIMAS realizes a full-digital control. Every automation with three phases sincron and asincron motors needs the full-digital control. Pimas develops algorithms like "Field Oriented Control" (FOC), AC/DC converters, generators and PFC (Power Factor Correctors).

Pc application Development

When the customer or the application needs an interface between software and hardware, Pimas develops also the application for the interface between hardware and software (under Windows or Linux). In this way, with a simple USB connection the customer can manage the remote application from his/her fixed location.

With this application server / client, for example, Pimas manages networks of regulators, with the exchange of information in real time with the external system. Other examples are the centralized control of a remote controls' system, or communication protocol via Bluetooth Low Energy (BLE) with control units for detecting the spatial position.

The application on the PC can be an integral part of a system designed entirely within Pimas, or a single element by the needs of the customer.